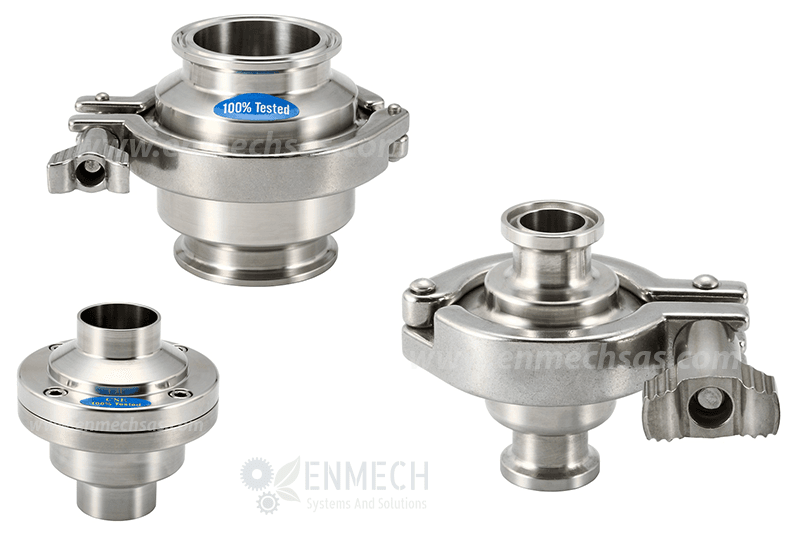

Our Check Valves are designed to prevent reverse flow. Concentric and Eccentric Styles as well as our tapered disk design are available for horizontal, vertical applications and work well without leaking while getting a return pressure.

Our specially designed Check valve can be used for many applications such as Food, Dairy, Beverage, Pharmaceutical, Chemical, and many other industries.

Our products have earned the 3A symbol, which requires an annual assessment to make certain each product conforms in all respects to the published standard.

All of the products have been 100% press tested before shipping.