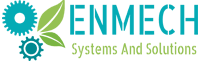

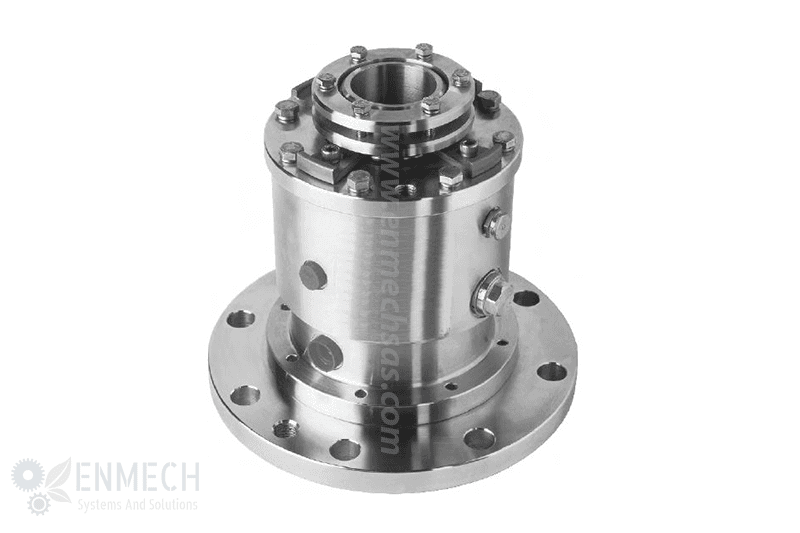

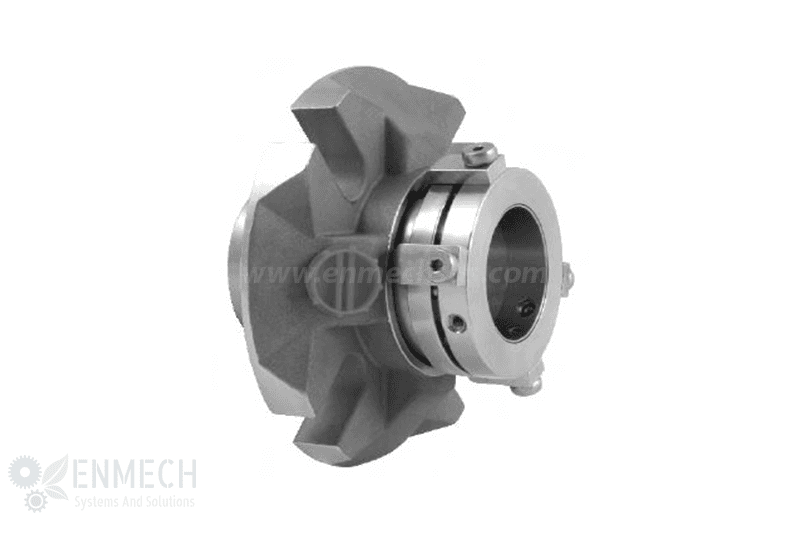

Agitator seals are widely used in chemical industries. These seals are pre-factory assembled and dynamically tested cartridge units.

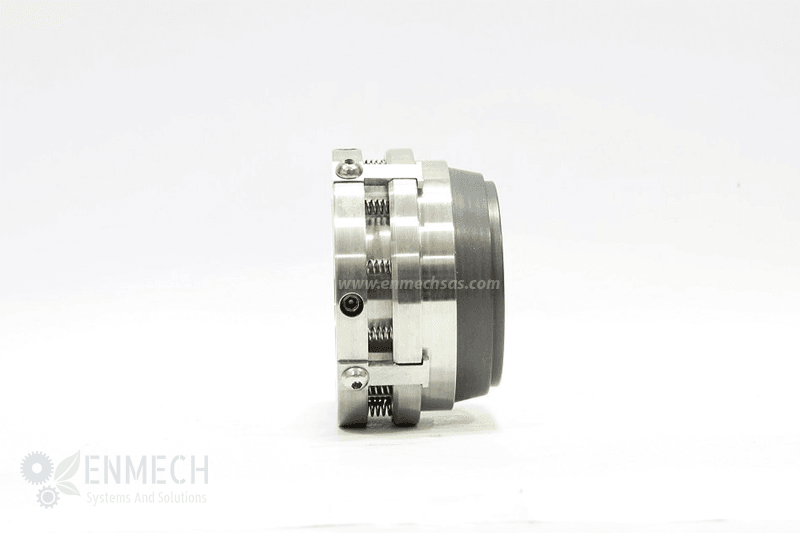

Agitator seals are available in Double back to back & Tandem arrangements.

Back to back double seals are used with pressurized buffer fluid preferably clean soft water because of its good transfer quantity. Fluids like oil, hydrocarbon solvents, etc. can also be used as buffer fluid by considering the corrosion resistance of the wetted parts and compatibility with main media being sealed.

The cartridge assembly has internal bearings which are close to the seal, ensuring optimum running and sealing conditions. These seals are supplied with cooling water jacket which ensures good running of the seal.

Agitator seals can be used in Petrochemical, Chemical and Hydrocarbon industries.

Equivalent to:

Eagle Burgmann AG1

Flowserve 2561-2564