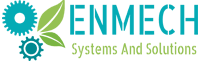

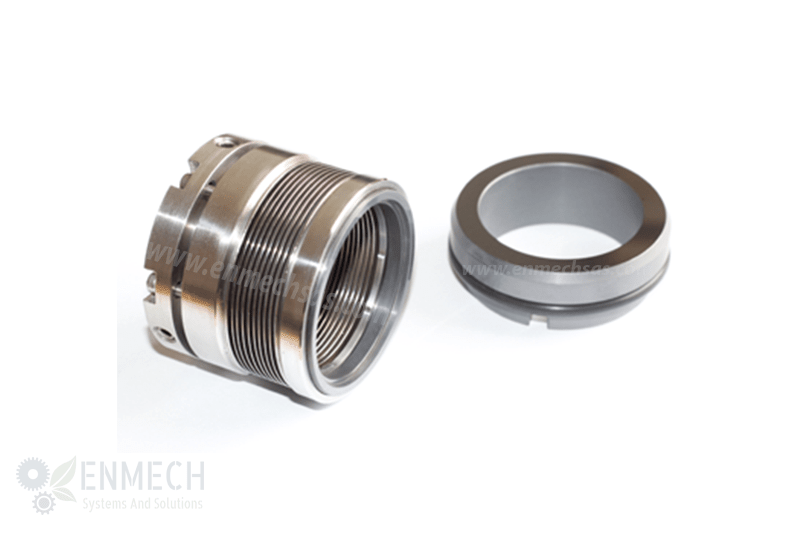

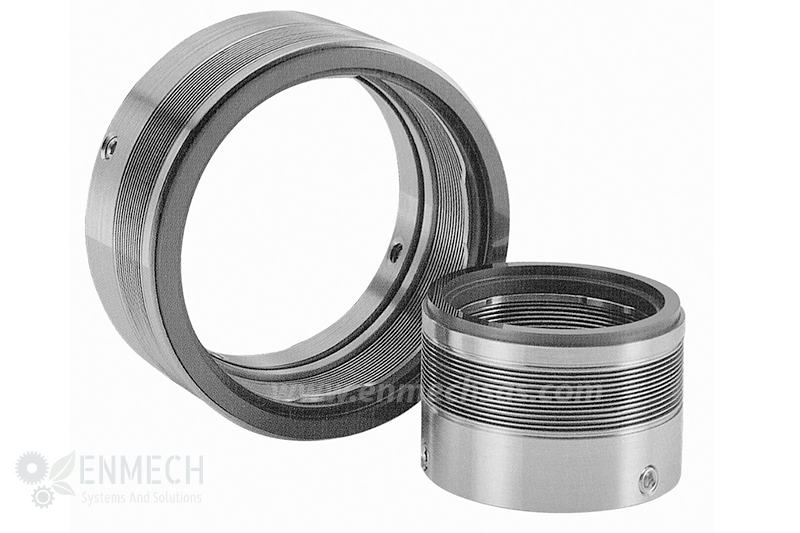

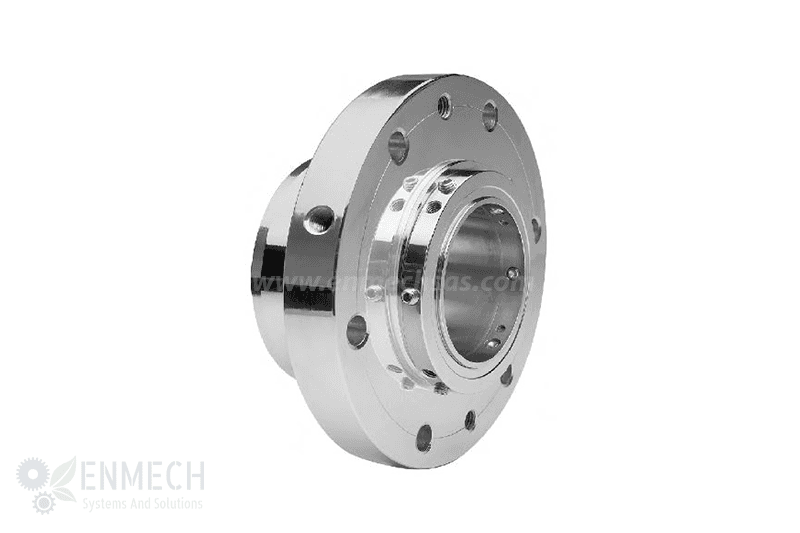

Metal Bellow Seals are used for high temperature applications such as Refinery, Petrochemical & Chemical industries. Due to its narrow seal cross section design, it can replace most type of seals used in ANSI pumps. Secondary seals are made up of Grafoil, which can withstand high temperatures up to 425°C.

It is resistant to abrasive particles in pumpage and facilitates no Shaft/Sleeve fretting.

The edge welded bellows are produced by stamping out a male and a female diaphragm and welding them edge to edge. These diaphragms typically have several ripples running from ID to OD.

We have the following Metal Bellow Seals:

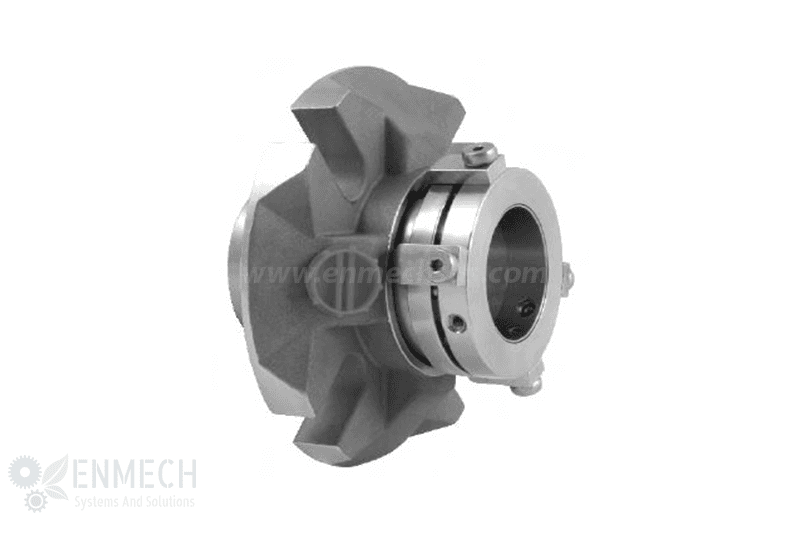

MBR – Rotating Bellow Assembly

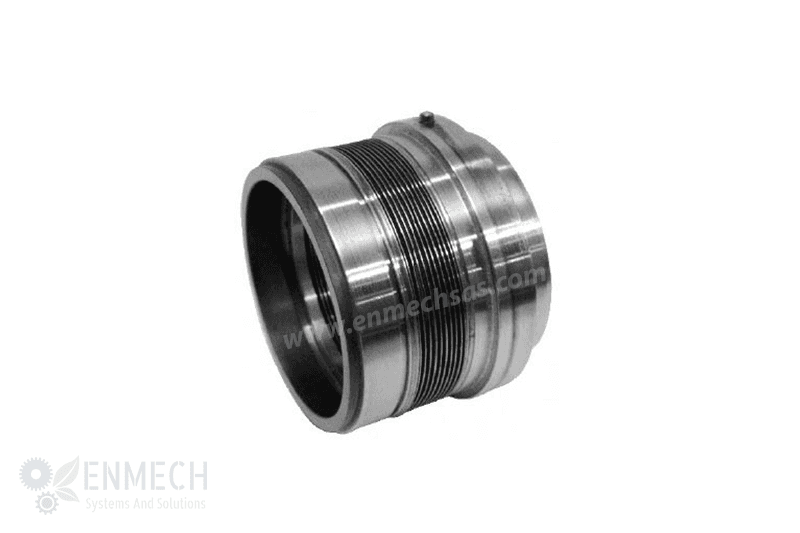

MBRC – Rotating Bellow Single Cartridge Assembly

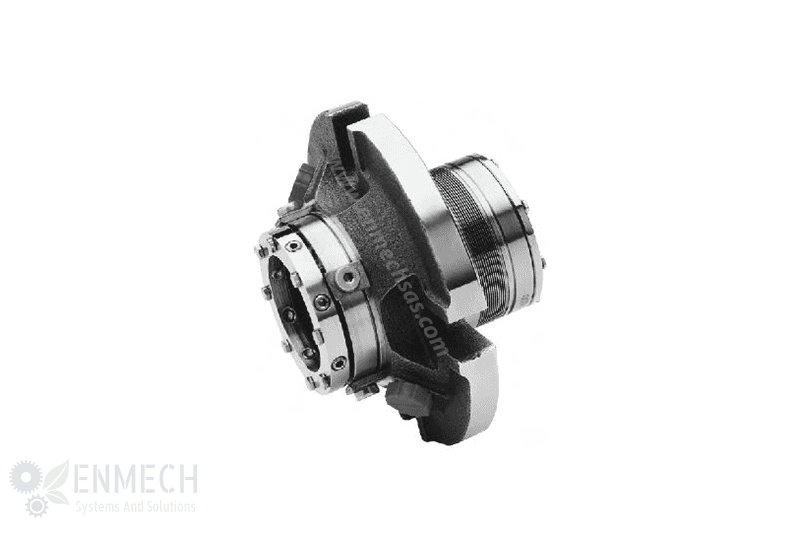

MBRDC – Rotating Bellow Double Cartridge Assembly

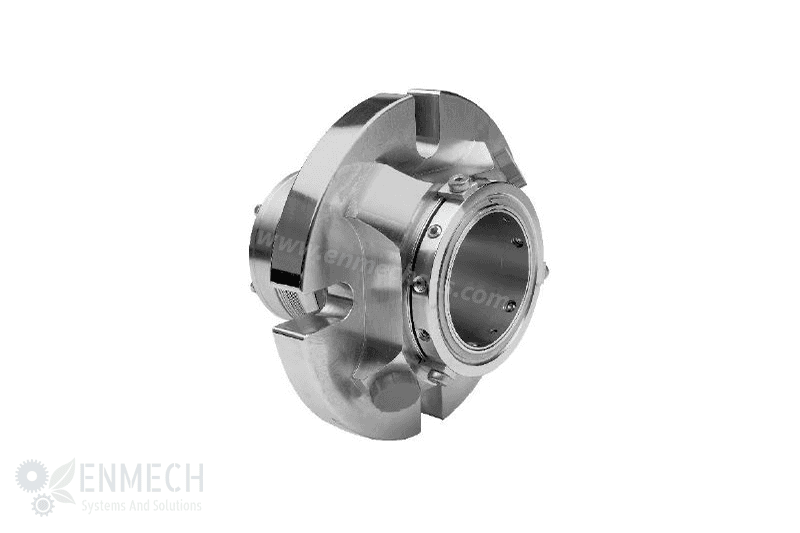

MBS – Stationary Bellow Assembly

MBSC – Stationary Bellow Single Cartridge Assembly

MBSDC – Stationary Bellow Double Cartridge Assembly

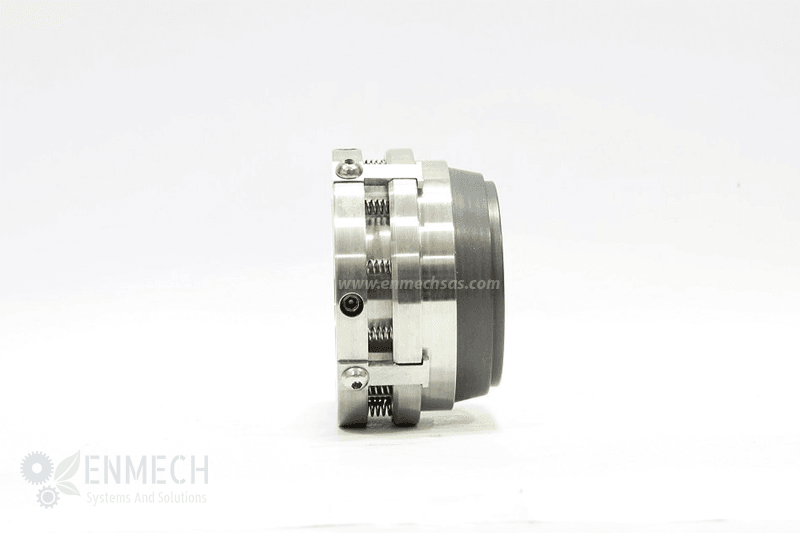

MBH Mechanical seal is a hook-sleeve design made for handling heat transfer media & high temperature hydrocarbons. The seal is self-cleaning without springs.

Equivalent to:

Eagle Burgmann Y13/ Y14/ Y15/ MFL85N/Mtex

John Crane Type 115WT

Flowserve BX/ BXB/ BXR